In San Francisco’s Mission Bay neighborhood, a 20-minute streetcar ride away from Google’s city offices, lies hidden a DNA factory.

That’s not an embellishment: Twist Bioscience, a venture-funded startup with investors including Russian billionaire Yuri Milner and Dr. Boris Nikolic, science advisor to Bill Gates, is writing millions of dollars worth of made-to-order synthesized DNA to silicon slabs, just a few inches in surface area.

The custom DNA market has been around for decades. But now, it’s poised to explode, as drugmakers and biology labs across the world turn to bespoke DNA samples to explore gene therapy and create new vaccines.

Now, there’s even more demand for custom DNA than ever before, as companies like Microsoft start to explore the possibilities of using DNA as a kind of super-intense hard drive to store lots of data even in the event of global apocalypse. In fact, Microsoft bought 10,000 strands of custom DNA from Twist earlier in 2016.

Twist Bioscience founders, left to right: Emily Leproust, Bill Banyai, Bill Peck

Twist Bioscience founders, left to right: Emily Leproust, Bill Banyai, Bill Peck

Twist CEO Emily Leproust, PhD, is very careful to say that while Twist didn’t invent the process of writing custom DNA, they’re applying a Silicon Valley mindset to making the process cheaper, easier, and more flexible than ever before.

“We are an engineering company, not a chemistry company,” saysLeproust.

(Oh, and in case you’re concerned, the DNA printed by Twist isn’t really “alive” by any measure. It’s just immensely tiny protein molecules.)

DNA machine

The key to the whole affair lies in a machine that’s so proprietary and important to Twist, I wasn’t allowed to take pictures and the company doesn’t publish any on the web.

Laboratories have been using machines synthesizing custom DNA since the early 1970’s. But the process has historically been time-consuming, slow, and prone to errors: It’s hard for say, Microsoft, to try a new experiment when you need to wait “weeks and weeks and maybe even months” for your custom DNA to arrive, Leproust says.

Twist’s top-secret solution automates much of the process with a machine that looks a little like the the inkjet printer you may have at your office. Little “ink” tanks hold the raw DNA bases that they can put into sequence, per the customers’ order.

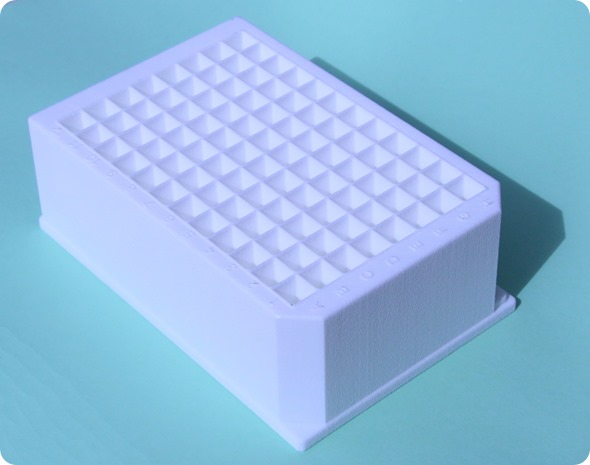

Zoomed into Twist Bioscience’s 10,000-well silicon plate. Each well has a 600 um diameter dimension.Zoomed into Twist Bioscience’s 10,000-well silicon plate. Each well has a 600 um diameter dimension.

Zoomed into Twist Bioscience’s 10,000-well silicon plate. Each well has a 600 um diameter dimension.Zoomed into Twist Bioscience’s 10,000-well silicon plate. Each well has a 600 um diameter dimension.

As the nozzle passes over a wafer of silicon, the same heat-tolerant mineral used for computer processors, it deposits 10,000 “blisters” of DNA bases every 21 minutes or so. Once the DNA is written to the wafer, it goes upstairs to a different laboratory for final processing and preservation, turning those “blisters” into deeper and more resilient “wells,” so it can be shipped out.

It’s like Kinko’s, but each print costs $1 million and might go to better mankind. With each wafer so valuable to the company, accuracy becomes key: You don’t want to put “the million dollars at risk,” as Leproust says.

Before each pass of the machine, a camera on the printer’s nozzle actually lines up with little crosshair targets on the silicon. When you’re dealing with microscopic bits of DNA, even getting it just a little bit off-kilter can result in the whole wafer having to be tossed out.

Then, after final processing, it’s taken off the silicon wafer and shipped out to customers in vials.

The business case

Okay, so each DNA-laden wafer sells for $1 million. But who’s buying?

Lots of biology labs have need for custom DNA, for everything from testing new vaccines to using gene therapy to develop new drugs.

But since custom DNA synthesis has historically been so slow and so pricey, labs have been forced by budgetary restrictions to go to other, cheaper alternatives, including cloning, where you give up the ability to custom-design your sample by making a literal genetic copy of your existing samples.

These puppies were cloned from each other.Getty Images

These puppies were cloned from each other.Getty Images

“They have more ideas than they had money,” Leproust says.

While Twist is charging customers a lot, it’s still as much as one-third the price as custom DNA has cost historically, Leproust says. And Twist’s turnaround time for delivering the DNA is days, not weeks. Customers can do science, tweak their parameters, and have a new sample to continue research all within a week.

Right place, right time

It’s a case of being in the right place at the right time, too. The science of genetic research is progressing nicely, making for a nice and growing market for Twist’s products. But the tech giants, notably Microsoft, are starting to experiment with using DNA for computer storage.

Big businesses, banks, and hospitals all have a habit of storing important archival data on old-fashioned magnetic tape storage, basically big cassette tapes. But those tapes tend to wear out after 30 years, meaning decades of data can be lost.

A Twist scientist prepares to load the silicon plate into the custom DNA writing machine.Twist Bioscience

A Twist scientist prepares to load the silicon plate into the custom DNA writing machine.Twist Bioscience

DNA, though, has a ton of potential. Unlike magnetic tape, DNA can stay totally intact and readable for as long as 10,000 years, in the right situation. Once the science gets far enough, DNA can store a lot of data, too: You can fit “the whole internet in a shoebox” one day, Leproust says.

Ultimately Microsoft Research estimates that one cubic millimeter of DNA can eventually store one exabyte, or one billion gigabytes of data. But the science is handicapped by the fact that it’s tough to actually store that much data.

And while technology trends may come and go, there’s going to be a need and capability to “read” human DNA for as long as there are humans, meaning it’s way more reliable.

In all cases, the market for custom genes is around $1 billion and $15 billion for DNA storage, Leproust says, and both markets are only growing as the world wakes up to its potential. And if everybody is going to want DNA, Leproust sees Twist as playing an important role in getting it to them.

“I want to be the one to make the DNA,” Leproust says.

This startup is selling $1 million plates of made-to-order, custom-built DNA to companies like Microsoft